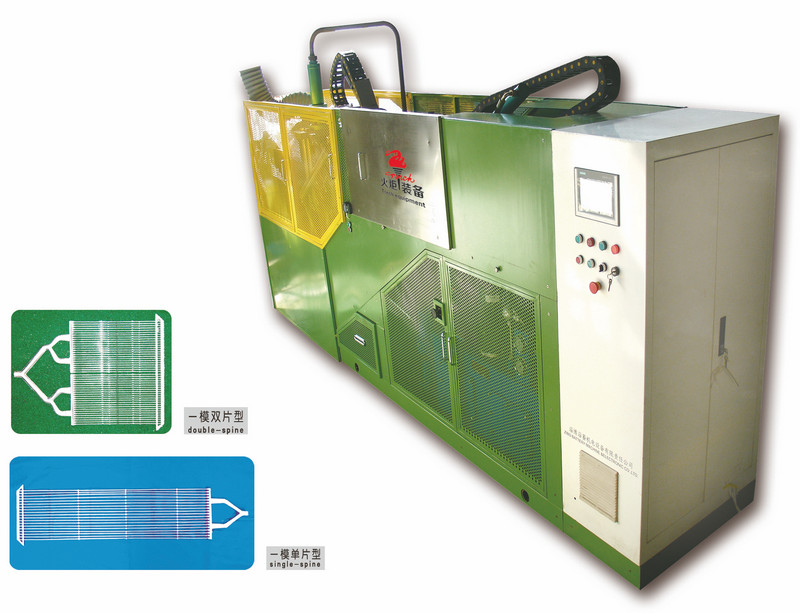

正板栅压铸机

知识产权名称:蓄电池自动板栅压铸机

发明专利

专利号:ZL200610044520.8

蓄电池自动板栅压铸机

压铸板栅在栅筋强度和结晶密实度等性能方面比浇铸板栅具有很大的优势,蓄电池正板栅的压铸生产在国外已经普及。

我公司生产的正板栅压铸机规格齐全、性能稳定、易于维护,已经获得国家发明专利。公司不断对产品进行升级换代,最新研制的一模双片高效压铸机和液压锁模式压铸机一经推向市场即得到客户的充分肯定。

Pressure die casted spines have more advantages than gravity casted spines at the strength and crystal density. The pressure die casting machine has been spread in foreign countries.

All kinds of pressure die casting machines made by our company are stable ad easy to maintain. Which have got the National Invention Patent. Our company sticks to upgrade the products. The new product which can make double-spines at one time and the hydraulic pressure die casting machine won wide praise from the customers once put into market.

设备用途: 适用于蓄电池正板栅压铸生产

Application: Used for making tubular positive plates.

设备构成: 压铸机主机、模具、剪切机

Composition: Die-casting machine、mould、shearing machine

栅筋长度: ≤620mm

Spine length: ≤620mm

冷却水: 0.2 MPa—0.3 MPa

Cooling water: 0.2-0.3 MPa

总功率:46-52KW

Total power: 46—52KW

性能、特点

○ 主要采用液压传动系统压铸,液压系统采用无级调速及压力控制;

○ 熔 铅 炉、喷嘴、模具温度采用电加热管加热方式,温控采用数字显示,具有高温报警功能;

○ 循环水通过模具冷却流道降温,模温自动控制并可调节;

○ 模具采用高强度、高硬度材料保证板栅成型;

○ 采用联锁安全装置,由压铸机自动完成合模、压铸、开模、顶出的工作循环,确保安全生产;

○ 电气控制采用触摸屏和PLC对系统进行程序控制,显示设备运行状态及实时工艺参数;具有

手动、自动、全自动控制功能,并具有动态演示,数字设定工艺参数的功能,使操作者更直观

的了解操作方法;

○ 模具锁紧方式采用机械锁紧或液压锁紧。

Performance & Features

○ It mainly uses hydraulic controlled die-casting system with step less regulator.

○ The lead melting pot, nozzle and mould are heated by electricity. And their temperatures are digitally displayed. It will alarm if the temperature gets too high.

○ Circulating cooling water flows through the cooling system of the mould. The temperature of the mould is auto-controlled and adjustable.

○ The mould is made of alloy with high strength and hardness. The working cycle of mould closing, pressing, opening and ejecting is completed automatically.

○ The touch screen and PLC are used in programmable control for the machine. The actual processing data are displayed on the monitor. It has manual, semi-automatic, fully automatic control functions, and features dynamic demonstration and digital setting for the process parameters; It is convenient for the operators to understand the operating process clearly.

○ There are two types of mould-locking style: mechanical clamping and hydraulic clamping.

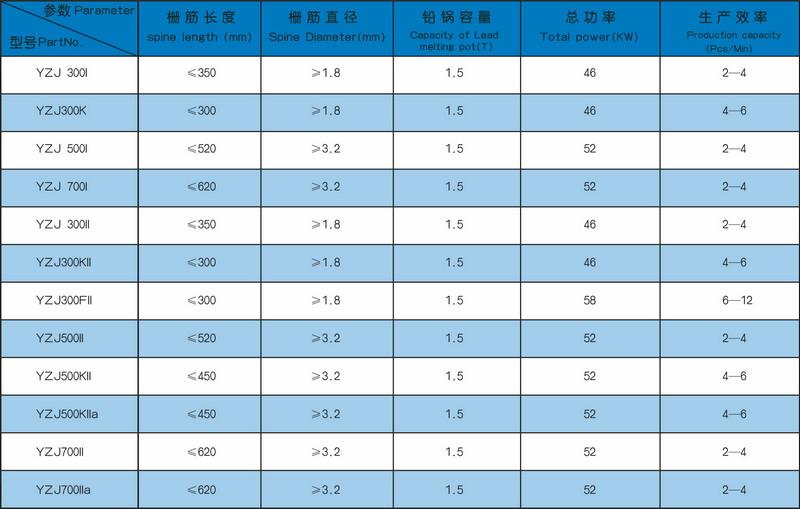

设备型号规格

备注 Remarks:Ⅰ —— 机械锁模 Mechanical clamping Ⅱ —— 液压锁模 Hydraulic clamping

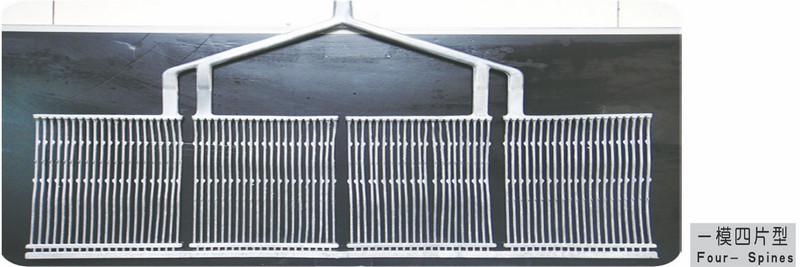

K —— 一模二片型 Double-Spines F —— 一模四片型 Four- Spines

a —— 自动取板型 Automatic Plates taking type